Food Grade Growth Factors

The Cultivated Meat industry is growing at a high pace. The cost of cell culture medium has been identified as one of the major cost drivers during upscaling of stem cell production and thus it is the main driver determining the final product cost.

Reprokine specializes in supply of animal growth factors for the meat industry. We aim to help companies in the cultivated meat industry accelerate and optimize cell culture techniques by supplying high grade multi-species growth factors to advance both the optimization and production stages of tissue growth and differentiation.

Laying the scientific foundation

reprokine is gearing to supply high volume low cost growth factors to supply demand of growing tech companies seeking a reliable source of growth factors for large scale cell culture applications such as in the cultivated meat industry.With an emphasis on the needs of cultivated meat startups , we are now developing species specific factors for various cell lines derived from porcine,bovine,ovine and chicken source.

Recombinant protein production in Escherichia coli (E. coli) involves several steps and poses various challenges. E. coli is commonly used for this purpose due to its well-established status as a cell factory for protein production, which lowers the costs and improves the yield of recombinant proteins. However, there are several challenges associated with this process, including the potential for protein toxicity to the host, aggregation in inclusion bodies, and the lack of post-translational modifications in prokaryotic cells, which can lead to protein misfolding and aggregation.To address these challenges, various strategies have been developed, such as optimizing protein expression, enhancing solubility, improving correct folding efficiency, and alleviating the host burden associated with protein overproduction. Despite these challenges, with careful selection of host strains, vectors, and growth conditions, most recombinant proteins can be cloned and expressed at high levels in E. coli

- Stably Transfected Adherent CHO Cells or Nonadherent Lymphoid Cell Lines: These systems are often used for the production of recombinant proteins, including therapeutics and research tools.

- Infection of Insect Cells by Recombinant Baculoviruses: This is an efficient alternative for the expression of recombinant proteins.

- Transient Expression in Mammalian Cells (e.g., COS Cells): This is often used for the production of smaller quantities of proteins.

The choice of a suitable expression system depends largely on the biochemical and biological properties of the protein of interest, as well as the nature of the planned experiments and the amount of recombinant protein required.

These systems offer the advantage of post-translational modifications, which are important for the proper folding and function of many proteins. The selection of the most suitable system is crucial for the successful production of recombinant proteins based on the specific requirements of the protein and the intended application

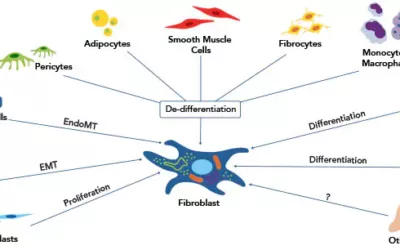

The most commonly used cell types in the cultivated meat industry include:

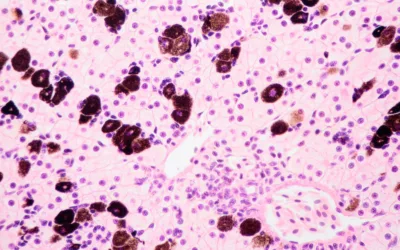

- Primary Adult Stem Cells: These are currently the most commonly utilized cell source for the production of cultivated meat. They possess the necessary proliferative capacity and differentiation potential for cultivated meat production

- Pluripotent Stem Cells: These cells have the ability to differentiate into a diversity of cell types and are attractive starting material for cultivated meat production

- Myoblasts and Mesenchymal Stem Cells (MSCs): These cell types have been used to produce cultured meat and are essential components in the production process. MSCs are particularly important and are used to multiply specific progenitor cells and differentiate into skeletal muscle cells, which are crucial for meat production

The majority of cultivated meat manufacturers work with well-characterized cell lines that have the ability to continuously proliferate over time. These cell lines are fundamental for the production of cultivated meat and are essential for the in vitro production of meat products.

The cell lines used in the cultivated meat industry are primarily derived from stem cells that can self-renew and differentiate into the cell types found in meat tissue, such as myofibers, adipocytes, fibroblasts, chondrocytes, and endothelial cells. The most likely starting cell types for use in cultivated meat production are embryonic stem cells and adult stem cell populations, which are more specialized and limited to creating cells of the same germ layer or organ type

Products

Contact Us

Publications and analyses

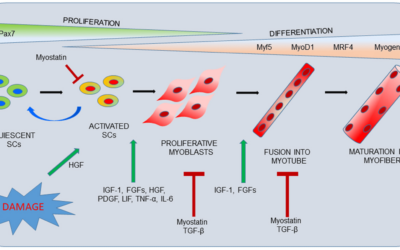

The role of Myokines in cultivated meat production

How do myoblasts differentiate into muscle cells